Cov khoom siv txhaj tshuaj pwm feem ntau yog tshuaj thiab lub cev muab faib ua acrylate, styrene thiab styrene.Txhua lub monomer muaj cov yam ntxwv sib txawv: acrylate muaj lub zog siab, thermal thiab tshuaj lom neeg ruaj khov: los ntawm qhov pom ntawm morphological, lub polymerization ntawm peb lub monomers tsim peb-theem copolymer, uas tau muab faib ua ob theem: ib qho yog theem txuas ntxiv ntawm styrene propylene diene. , thiab lwm yam yog lub dispersed theem ntawm polybutylene roj hmab.

Kev ua haujlwm ntawm ABS feem ntau yog nyob ntawm qhov kev faib ua feem ntawm peb lub monomers thiab cov qauv molecular ntawm ob theem.Qhov no tso cai rau kev hloov pauv zoo hauv cov khoom tsim thiab tso cai rau kev tsim ntau pua qhov sib txawv zoo thiab cov ntaub ntawv pwm ntawm lub khw.Cov kev txhaj tshuaj molding thiab pwm cov ntaub ntawv uas muaj qhov zoo sib txawv muaj cov yam ntxwv sib txawv, xws li kev ua haujlwm siab, tsis muaj roj thiab siab tiav, thiab cov yam ntxwv kub deformation.ABS txhaj tshuaj molding, cov khoom siv pwm nrog cov machinability siab, cov yam ntxwv zoo li, tsis tshua muaj creep, zoo heev dimension stability thiab muaj zog muaj zog.Dej ntsuas dej thiab lwm yam khoom siv coj mus muag, lub tes tsho cable, cov khoom siv kho tshuab, zawv zawg mechanisms thiab bearings.Lub tsheb vaj huam sib luag,cuab yeej alarm, log cover, daim iav thawv, tub yees, plaub hau tshuab, tov khoom, zaub mov ua tshuab, nyom mower, xov tooj lub rooj, ntaus ntawv ntaus ntawv, golf laub, thiab lwm yam.

Cov txheej txheem ntawm kev txhaj tshuaj pwm: nws yuav tsum tau qhuav ua ntej ua.Qhov kev pom zoo kom qhuav yog 80 ~ 90 teev tsawg kawg, thiab cov khoom siv kub yuav tsum qis dua 0.1%.Melting kub: 210 ~ 280c;Pom zoo kub: 245 ℃.Pwm kub: 25 ~ 70C, pwm kub yuav cuam tshuam rau saum npoo ntawm cov khoom yas, thaum qhov kub thiab txias yuav txo qhov chaw tiav.Txhaj siab: 500 ~ 1000bar.Txhaj ceev: nruab nrab ceev.

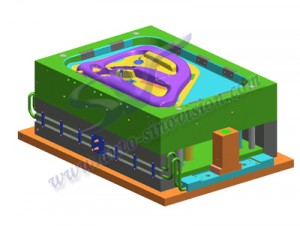

Covtxhaj tshuaj pwmtsim cov khoom siv ABS yas tshuab ua ke cov yam ntxwv ntawm peb lub ntsiab lus.Ntawm lawv, Acrylonite muaj siab hardness, siab zog, kub tsis kam thiab corrosion kuj;Butadiene muaj kev cuam tshuam thiab toughness;Styrene muaj luster siab, yooj yim rau xim thiab txheej txheem;Kev soj ntsuam saum toj no ntawm cov yam ntxwv ntawm peb yam sib txawv ua rau ABS txhaj tshuaj pwm cov ntaub ntawv tsim los rau hauv peb "muaj zog zoo" thiab "rigid" kev ua tau zoo ntawm kev ua haujlwm siab ntawm cov thermoplastics.Kho qhov kev faib ua feem ntawm peb cov khoom xyaw tseem ceeb ntawm ABS, thiab nws qhov kev ua tau zoo yuav hloov raws li qhov yuav tsum tau ua ntawm ntau cov ntaub ntawv siv ntawm cov tuam txhab, xws li siab tiv thaiv ABS, ABS tiv thaiv tshav kub, thiab siab gloss ABS.Kev tshawb fawb ntawm ABS txhaj tshuaj molding cov ntaub ntawv muaj cov txheej txheem zoo, uas tuaj yeem tsim los ntawm kev txhim kho kev txhaj tshuaj molding, extrusion, kub molding thiab lwm txoj hauv kev tib lub sijhawm, los yog ncaj qha los ntawm sawing, drilling, filing, sib tsoo thiab lwm yam.Nws tuaj yeem sib xyaw nrog cov kuab tshuaj organic, thiab tseem tuaj yeem tswj cov txheej txheem thiab cov ntaub ntawv ntog zoo (xws li electroplating) thiab kho.ABS yas kuj yog ib qho kev xaiv zoo tshaj plaws rau cov neeg uas tsis tuaj yeem hloov cov ntoo thiab cov khoom siv hauv tsev.ABS txhaj tshuaj pwm cov ntaub ntawv muaj qee lub zog siab, lub teeb yuag thiab siab tawv tawv Nws yog du, yooj yim los ntxuav, qhov ntev stability, zoo creep kuj, thiab haum rau electroplating nyob rau hauv Suav teb.Nws daim ntawv thov kev tswj xyuas haujlwm tseem tab tom nthuav dav.ABS yas yog dav siv nyob rau hauv Suav kev lag luam.Qhov zoo ntawm ABS txhaj tshuaj molding khoom feem ntau yog siv rauhluav taws xob enclosures, thawv, qhov chaw, khoom ua si, thiab lwm yam.

Post lub sij hawm: Oct-21-2022