Txhaj pwm polishing muaj ob lub hom phiaj;Ib qho yog txhawm rau txhim kho qhov smoothness ntawm cov pwm, kom qhov chaw ntawm cov khoom tsim los ntawm cov pwm yog du, zoo nkauj thiab zoo nkauj.Lwm qhov yog ua kom cov pwm yooj yim rau demould, kom cov yas yuav tsis daig rau pwm thiab tsis tuaj yeem raug tshem tawm.

Kev ceev faj rautxhaj tshuaj pwmpolishing yog raws li nram no:

(1) Thaum lub pwm kab noj hniav tshiab pib ua tshuab, lub workpiece nto yuav tsum tau kuaj xyuas ua ntej, thiab qhov chaw yuav tsum tau ntxuav nrog roj av, kom cov roj zeb nto yuav tsis daig nrog cov av thiab yog li poob qhov kev txiav.

(2) Cov pob zeb ntxhib yuav tsum tau grinded nyob rau hauv qhov kev txiav txim ntawm qhov nyuaj rau zom ua ntej thiab yooj yim zom, tshwj xeeb tshaj yog rau qee qhov chaw tuag uas nyuaj rau zom, qhov tob hauv qab yuav tsum tau grinded ua ntej,

(3) Qee qhov workpieces yuav muaj ob peb daim sib dhos ua ke rau polishing.Ua ntej, grind cov ntxhib nplej los yog cov hmoov nplej ntawm ib qho chaw ua haujlwm sib cais, thiab tom qab ntawd zom tag nrho cov workpieces ua ke kom smoothing.

(4) Rau cov khoom ua haujlwm nrog lub dav hlau loj lossis sab dav hlau, siv cov roj pob zeb los zom cov pob zeb ntxhib thiab tom qab ntawd siv cov ntawv hlau ncaj nraim rau kev kuaj xyuas lub teeb thiab ntsuas los xyuas seb puas muaj qhov tsis sib xws lossis tsis zoo.Yog hais tias muaj ib qho undercut, nws yuav ua rau nyuaj rau demoulding los yog strain ntawm workpieces.

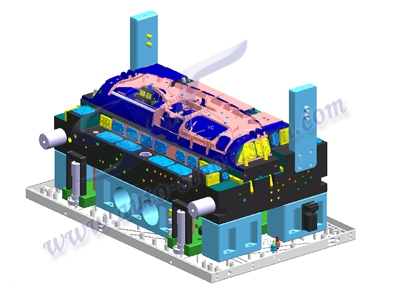

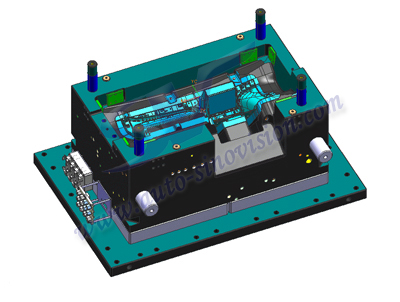

Txhaj tshuaj molding ua chaw tsim tshuaj paus

(5) Txhawm rau kom tsis txhob ua tib zoo saib xyuas qhov xwm txheej uas cov khoom ua haujlwm tuag tau tsim cov buckle lossis qee qhov chaw sib txuas yuav tsum tau tiv thaiv, cov saw saw tuaj yeem siv rau pasting lossis sandpaper tuaj yeem siv rau pasting ntawm ntug, yog li kom tau txais kev tiv thaiv zoo tshaj plaws.

(6) rub lub dav hlau pwm rov qab, thiab tso tus kov ntawm tus rub whetstone kom tiaj tus li ua tau, tsis pub tshaj 25 °;Vim tias txoj kab nqes loj heev, lub zog yog xuas nrig los ntawm sab saum toj mus rau hauv qab, uas yooj yim ua rau ntau cov kab ntxhib ntawm lub workpiece.

(7) Yog hais tias qhov saum npoo ntawm lub workpiece yog polished nrog daim ntawv tooj liab lossis xyoob ntawv nias nrog cov ntawv xuab zeb, cov xuab zeb yuav tsum tsis txhob loj dua qhov chaw ntawm lub cuab yeej, txwv tsis pub nws yuav zom rau qhov chaw uas yuav tsum tsis txhob grinded.

(8) Cov duab ntawm cov cuab yeej sib tsoo yuav tsum nyob ze rau cov duab ntawm cov pwm saum npoo, thiaj li xyuas kom meej tias lub workpiece tsis deformed los ntawm kev sib tsoo.

Piv txwv li,yas khoom siv hluav taws xob plhaub, yasntim khoom noj, thiab lwm yam. Yog hais tias cov ntsiab lus saum toj no ua tau zoo, polishing tsos ntawm txhaj tshuaj pwm yuav zoo nkauj heev.

Post lub sij hawm: Oct-14-2022