-

Me me txhaj molded yas bracket

· Txhaj tshuaj molding

· kev cai qhov chaw

· yas tuav

-

Kev cai txhaj tshuaj molded roj hmab stopper

· Txhaj tshuaj molding

· kev cai qhov chaw

· Plug yas -

Nplaim retardant txhaj molded yas npog

· Txhaj tshuaj molding

· kev cai qhov chaw

· yas npog -

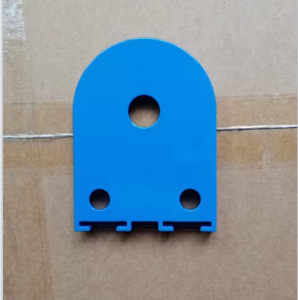

Txhaj yas Custom Brackets

· Txhaj tshuaj molding

· kev cai qhov chaw

· yas tuav -

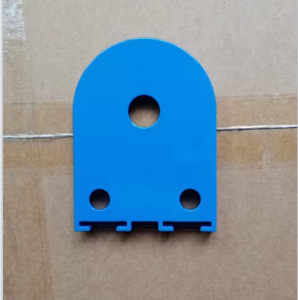

Txhaj yas Custom Brackets

· Txhaj tshuaj molding

· kev cai qhov chaw

· yas tuav -

Txhaj yas PA6 txiv ntseej

· Txhaj tshuaj molding

· kev cai qhov chaw

· yas txiv ntoo -

Customized UL94 V0 Nplaim Retardant Electronic Cov Khoom Siv Yas Tsev

· Txhaj tshuaj molding

· phaj yas

UL94 V0 nplaim retardant qib -

Kev cai Txhaj Moulded Electronics Yas Sheets

· Txhaj tshuaj molding

· kev cai yas ib feem

· phaj yas -

Kev cai txhaj tshuaj molded yas electronics lub cev

· Txhaj tshuaj molding

· kev cai yas ib feem

· yas lub cev tseem ceeb ntawm cov khoom siv hluav taws xob -

Kev Cai Txhaj Tshuaj Yas Electronics Housing

· Txhaj tshuaj molding

· kev cai yas ib feem

· yas plhaub -

Kev Cai Txhaj Tshuaj Plastic Roj Teeb Npog

· Txhaj tshuaj molding

· kev cai yas ib feem

· cov roj teeb yas npog -

Customized Txhaj Moulded Yas Laminations

· Txhaj tshuaj molding

· kev cai yas ib feem

· yas npog

-

Dbh-15p (poj niam) vuam hlau hom koob dawb kua nplaum txuas

Khoom npe: dbh-15p (poj niam) vuam hlau hom koob dawb kua nplaum

Kub tiv thaiv: 230 degrees

Hom interface: HDMI

Yam ntxwv: kub tsis kam 230 ° C

Scope ntawm daim ntawv thov: dav siv nyob rau hauv txhua yam khoom siv hauv tsev, cov khoom ua si hluav taws xob

Cov khoom siv digital, cov cuab yeej siv hauv chaw ua haujlwm niaj hnub, kev lag luam tswj thiab saib xyuas cov khoom siv sib txuas lus, thiab lwm yam. -

Lub suab nrov gasket

Cov lus piav qhia: Louderspeaker gasket

Kev Lag Luam lossis Cov Neeg Siv Khoom: Canada

Daim ntawv thov: gasket rau audio system / Louderspeakers

Khoom siv: NBR

Kev ua: roj hmab molding.

Tshwj xeeb ntawm cov khoom no: Antistatic.

TSIS MUAJ KEV HLUB.Mould tswv cuab yog peb cov neeg siv khoom.

-

PF sab saum toj thiab hauv qab npog rau PG020 barbecue tshuab, PF txhaj, fireproof, kub resistant.

Nqe lus piav qhia:

PF sab saum toj thiab hauv qab npog rau PG020 barbecue tshuab, PF txhaj, fireproof, kub resistant.

Khoom siv: PF (phenolic compound);

Qhov hnyav: 730g;

Kev ua lag luam: xa tawm mus rau Denmark;

Customized tsim, tseeb version.Fireproof, kub resistant.

Bakelite, tseem hu ua bakelite thiab tshuaj phenolic resin, muaj zog txhua yam, zoo rwb thaiv tsev, kub tsis kam thiab corrosion kuj.Yog li ntawd, nws yog dav siv nyob rau hauv ntau yam khoom siv hluav taws xob, xws li hloov, lub cev muaj zog plhaub, chav ua noj kov, thiab lwm yam.

Bakelite txhaj tshuaj molding khoom yog cov yam ntxwv ntawm rwb thaiv tsev, kub tsis kam, tsis muaj dej nqus thiab siab zog, yog li lawv feem ntau yog siv rau hauv cov khoom siv hluav taws xob.Vim tias nws muaj cov rwb thaiv tsev zoo thiab cov yas siab zoo li ntoo, nws yog hu ua bakelite.Bakelite yog ua los ntawm cov hmoov phenolic resin, tov nrog sawdust, asbestos los yog av nplaum, thiab ces thermosetting nrog pwm ntawm kub.Phenolic resin yog ib hom tib neeg hluavtaws cob. -

phenolic txhaj molding bakelite lauj kaub hlaws

Qhov no yog cov khoom bakelite siv rau cov khoom siv hluav taws xob.Nws tuaj yeem siv rau txhua yam khoom siv hauv tsev, keyboards thiab khoom siv hluav taws xob.Nws cov yam ntxwv tseem ceeb yog rwb thaiv tsev, kub tsis kam thiab siab mechanical zog.Cov khoom loj tuaj yeem tsim tau raws li koj cov duab kos thiab tsim nyog rau cov khoom siv uas siv rau hauv ntau qhov chaw kub. -

phenolic txhaj plhaub ntawm hluav taws xob mov cooker

SV Plastic Hardware CO., LTD.yog nyob rau hauv Huangyan Town, Zhejiang, Suav.Nws tau koom nrog kev txhaj tshuaj molding rau ntau tshaj kaum xyoo.Nws muaj bakelite, BMC txhaj tshuaj molding thiab precision yas txhaj molding.Nws cov khoom siv dav siv hauv txhua yam khoom siv hauv chav ua noj, electromechanical, khoom siv hauv tsev thiab precision yas txhaj tshuaj molding khoom, phau ntawv, xov tooj ntawm tes pib lub plhaub, thiab lwm yam.

Lub tuam txhab muaj ib pab neeg ua haujlwm muaj zog thiab tau cog lus los tsim cov khoom zoo rau cov neeg siv khoom.Lub tuam txhab siv tag nrho ISO9001 thiab iatf16949 kev tswj xyuas zoo thiab muaj kev ruaj ntseg zoo-paub cov neeg siv khoom hauv tsev thiab txawv teb chaws. -

Tsheb OEM pem hauv ntej bumper

Kev Lag Luam lossis Cov Neeg Siv Khoom: Lub Tebchaws Yelemees;

Khoom siv: Pwm -P20, molded qhov chaw -engineering PP / Compounded PP;

Kev Ua: Txhaj.

Daim Ntawv Thov: Tsheb, OEM, txhaj tshuaj;

Tshwj xeeb ntawm cov khoom no: OEM tsheb qhov chaw, loj loj

Vim li cas feem ntau ntawm sab hauv thiab sab nrauv trim nyob rau hauv kev lag luam tsheb ua los ntawm cov ntaub ntawv yas?Tsis muaj lwm yam laj thawj.Plastics muaj cov khoom siv zoo heev thiab ntau txoj hauv kev ua haujlwm.Cov txheej txheem sib txawv xws li kev txhaj tshuaj molding, tshuab moulding thiab blister tuaj yeem ua tau raws li cov txheej txheem molding ntawm cov khoom sib txawv, tshwj xeeb tshaj yog qhov nyuaj ntawm cov tsheb.Kev xaiv ntawm kev txhaj tshuaj molding tshuab ntawm cov qauv sib txawv tuaj yeem ua tau raws li qhov yuav tsum tau muaj ntawm cov khoom sib txawv xws li tsheb bumpers, ntsuas vaj huam sib luag thiab tsheb baffles Txhaj tshuaj molding ntau lawm ntawm automotive qhov chaw nrog qhov sib txawv thiab lwm yam ntxwv.

Kev ua tau zoo ntawm tsheb complex yas qhov chaw:

1. Cov yas tuaj yeem ua tiav thiab tsim ib zaug, nrog lub sijhawm ua haujlwm luv thiab lav qhov raug.

2. Cov yam ntxwv ntawm elastic deformation ntawm cov khoom yas tuaj yeem nqus tau ntau lub zog ntawm kev sib tsoo, muaj cov cushioning zoo rau kev cuam tshuam, thiab tiv thaiv tsheb thiab cov neeg caij tsheb.Plasticized dashboard thiab lub kauj log yog siv nyob rau hauv cov tsheb niaj hnub los txhim kho cushioning.Pem hauv ntej thiab nraub qaum thiab lub cev trim strips yog ua los ntawm cov ntaub ntawv yas los txo qhov cuam tshuam ntawm cov khoom sab nraum lub tsheb ntawm lub cev.Cov yas kuj muaj kev ua haujlwm ntawm absorbing thiab attenuating vibration thiab suab nrov, uas tuaj yeem txhim kho kev nplij siab.

3. Yas muaj zog corrosion kuj thiab yuav tsis corrode yog puas hauv zos.

4. Los ntawm kev ntxiv cov fillers sib txawv, plasticizers thiab hardeners, plastics uas yuav tsum tau muaj cov khoom yuav tsum tau npaj kom tau raws li qhov yuav tsum tau ntawm daim ntawv thov ntawm qhov sib txawv ntawm lub tsheb.Dab tsi yooj yim dua yog tias cov xim sib txawv tuaj yeem raug hu tawm los ntawm cov khoom siv ntxiv kom txuag tau qhov teeb meem ntawm kev pleev xim.Qee qhov yas kuj tuaj yeem ua electroplated. -

Bakelite lub teeb cap

Hluav taws xob ntoo board, tseem hu ua kua nplaum board, yog ua los ntawm high-zoo bleached ntoo stacking ntawv thiab paj rwb lint daim ntawv raws li reinforcement, bakelite thiab phenolic resin ua los ntawm cov tshuaj tiv thaiv ntawm high-purity thiab tag nrho hluavtaws petrochemical raw cov ntaub ntawv raws li resin nplaum.

Bakelite yog ua los ntawm cov hmoov phenolic resin, tov nrog sawdust, asbestos lossis av nplaum, thiab nias tawm ntawm cov khoom tiav los ntawm pwm ntawm qhov kub thiab txias.Phenolic resin yog ib hom hluavtaws cob hauv ntiaj teb.

1. T385j txhaj tshuaj molding, thaum t373j muaj kev ua haujlwm zoo hluav taws xob, ua haujlwm kub thiab nplaim taws.

2. Bakelite hmoov tuaj yeem tiv taus qhov kub ntawm 275 ℃.

3. Qhov nruab nrab shrinkage ntawm bakelite hmoov yog 0.8%, thiab expansion coefficient ntawm bakelite bakelite tom qab molding thiab kho yog 0.14%.

4. Bakelite hmoov yuav tsis hlawv, tsuas yog coking.

5. Composition: phenolic resin, ntoo hmoov, hardener thiab additives, xws li curing agent, plasticizer, colorant, lubricant thiab curing accelerator.

6. Phenolic resin: cov resin tau los ntawm polycondensation ntawm phenolic tebchaw thiab aldehydes (tsuas yog cov condensate nrog) yog hu ua phenolic resin.

7. Bakelite: phenolic resin muaj lub zog txhua yam thiab kev ua haujlwm ruaj khov, hardness, hnav tsis kam, kub tsis kam, nplaim taws ua haujlwm, tsis kam mus rau feem ntau cov tshuaj reagents, tsis tshua muaj noo noo nqus thiab zoo hluav taws xob rwb thaiv tsev kev ua tau zoo.Nws yog cov khoom siv insulating zoo tagnrho, feem ntau hu ua bakelite.

8. Bakelite yog plasticized ntawm 70 ~ 90 ℃, muaj viscosity thiab fluidity ntawm 90 ~ 120 ℃, thiab mam li nco dheev hardens ntawm txog 160 ℃, ua tsis melting khoom thiab hardening cov tshuaj tiv thaiv. -

Lub plhaub yas ntawm hluav taws xob hlau

Cov txheej txheem molding ntawm cov khoom bakelite suav nrog nias molding thiab txhaj tshuaj molding, yog li feem ntau cov ntaub ntawv bakelite kuj tau muab faib ua cov ntaub ntawv xovxwm thiab cov ntaub ntawv txhaj tshuaj.Feem ntau, tus nqi ntawm cov xovxwm molding yog tsawg, tab sis kev siv zog ntawm cov neeg ua haujlwm siab, qhov precision ntawm cov khoom yog tsawg, thiab cov txiaj ntsig tsis siab.Txhaj tshuaj molding yog zoo dua li xovxwm molding.Txawm hais tias nws qhov kev nqis peev ib zaug yog siab, kev siv zog ntawm cov neeg ua haujlwm yog me me, qhov tseeb ntawm cov khoom yog siab, thiab cov txiaj ntsig kuj siab.Yog li ntawd, nws muaj cov qauv ntawm maj mam hloov xovxwm molding.

Feem ntau muaj cov ntaub thaiv npog cua sov rau saum thiab hauv qab ntawm qhov tuag.Qhov no feem ntau yog vim qhov kub thiab txias yuav tsum tau nce mus rau 160-180 ℃ thaum lub pwm pwm tsim pwm.Cov cuab yeej tau ntxiv kom tsis txhob muaj pwm kub los ntawm kev xa mus rau lwm qhov ntawm lub tshuab, cuam tshuam rau kev ua haujlwm ntawm lub tshuab thiab txo cov cua sov.Tam sim no, peb cov khoom siv cov qauv no.